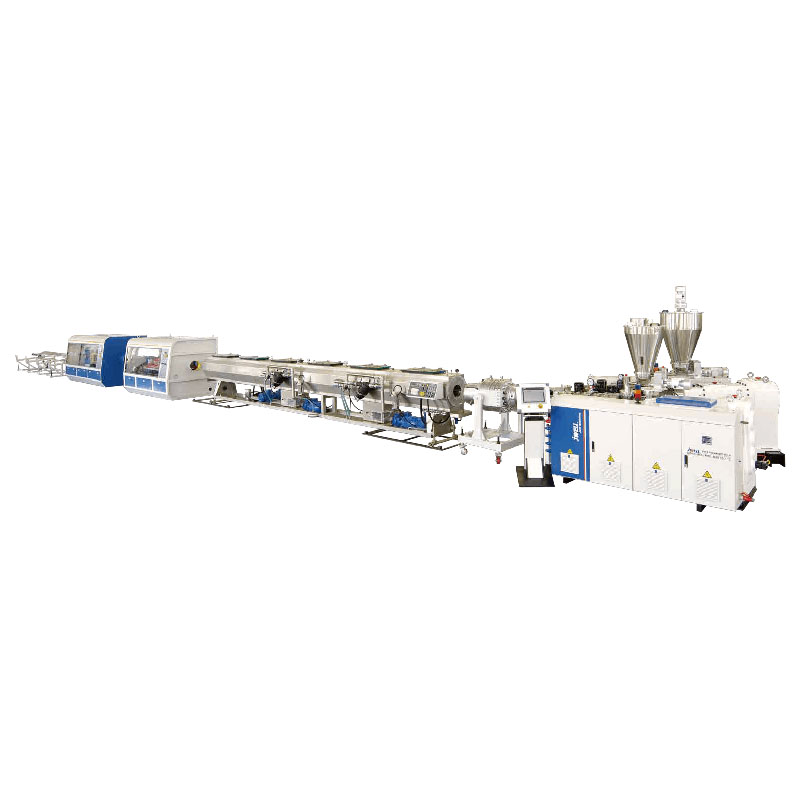

Small-caliber PE/PPR/PE-RT/PA Single-pipe, Dual-pipe High-speed Extrusion Production Line

Small-caliber PE/PPR/PE-RT/PA Single-pipe is mainly used to produce pipes of various diameters and wall thicknesses that are widely used in residential water supply systems, industrial water transportation, and compressed air transportation. In the history of international pipe development, PP-R has the characteristics of low price, non-toxic, non-corrosion, high temperature resistance, and convenient installation. The production line can also be used to produce PERT floor heating pipes.

Small-caliber PE/PPR/PE-RT/PA Single-pipe is a new product developed by China JWELL by introducing and absorbing foreign advanced technology. Its key components, such as screw and machine head, are specially designed according to the characteristics of PP-R. The control electrical appliances adopt frequency conversion speed regulation, and the main electrical components assume imported brand-name products; the entire production line has the characteristics of high output, stable quality, and small product error and is the first-class equipment in today's plastic machine industry. At the same time, the production line is suitable for the production of PP-C, PE-X cross-linked pipes, and polyolefins. The company can provide process formulas and turnkey projects.

Small-caliber PE/PPR/PE-RT/PA Single-pipe Machine Features

● Small-caliber PE/PPR/PE-RT/PA Single-pipe advanced Siemens computer control system (PLC), to achieve full line integration, closed-loop control, effortless data analysis (energy consumption display and research), remote diagnosis (quick after-sales service), equipment maintenance reminders (humanized reminders), saving raw materials (advanced weight control technology, keeping the tube wall thickness within a very narrow tolerance range), etc.

● The helically grooved feed barrel and BM barrier mixing structure screw with 38L/D ratio achieve a high output of polyolefin material and high quality of the pipe. Carbide-coated screw and bimetallic barrel ensure long and efficient operation.

● High torque precision gearbox and AC variable frequency or permanent magnet servo motor ensure long-term high output and low energy consumption.

● Optimized high-speed molds and multi-disc or wet calibrators ensure high-quality tubing in high-speed production.

● The unique frequency conversion vacuum automatic control device can perfectly solve the noise and realize energy-saving and precise pipe diameter.

● China JWELL traction device adopts a servo motor with a wide traction range and high synchronous operation accuracy. It adopts a digital communication interface with the extruder, equipped with a stable and perfect cutting knife (small diameter) and a chip-free double-blade cutter (large diameter).

● Two-layer and multi-layer co-extrusion can also be realized by changing part of the production line.

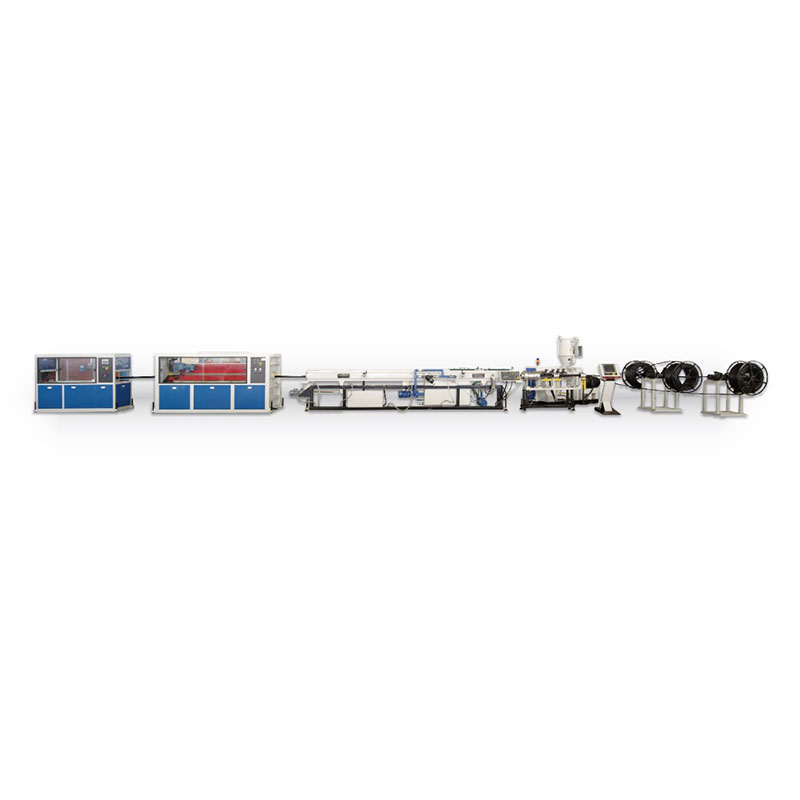

Performance & Advantages

The main screw adopts BM high-efficiency type, and the output is fast and plasticized well. The wall thickness of pipe products is precisely controlled and very less waste of raw materials.

Tubular extrusion special mold, water film high-speed sizing sleeve, equipped with integrated flow control valve with scale. Servo-controlled high-speed double-belt haul-off unit, supporting high-speed chipless cutter and winder, adapt to high-speed production operation.

A dual pipe extrusion lines can double the output and occupy less factory space.

Main Technical Parameters

| Type | Pipe Spec (mm) | Extruder | Main Power(kw) | Output (kg/h) |

| PE/PERT 75 | Ø20~Ø75 | JWS-H 60/40 | 110 | 380~420 |

| 90 | 350~400 | |||

| JWS 65/33 | 75 | 200~240 | ||

| PPR 75 | Ø20~Ø75 | JWS-H 60/40 | 110 | 300~340 |

| 90 | 280~320 | |||

| JWS 65/33 | 75 | 160~195 | ||

| PE/PERT 32 | Ø16~Ø32 | JWS-H 60/40 | 110 | 380~420 |

| 90 | 350~400 |

Small caliber PE PPR PE RT PA Single pipe Dual pipe High speed Extrusion Production Line application

Small caliber PE PPR PE RT PA Single pipe Extrusion Production Line application

Single pipe Dual pipe High speed Extrusion Production Line application

FAQ

● International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW.

● Terms of Payment: LC, T/T.

● Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months.

● Number of Foreign Trading Staff:>50 People.

Yes, We own 5 manufacturing bases and sales center in Shanghai, Suzhou, Changzhou, Zhou Shan, Dongguan China.

Jwell made the first Chinese screw and barrel in 1978 in brand name Jinhailuo. After more than 40 years development.

JWELL is one of the biggest extrusion machine supplier in China with 300design&test engineer, 3000 employees.

Jwell has become the premier supplier of extrusion lines and reliable business partners. Welcome to drop in us.

Our machines taking the European standards and follow the Germany type of business, we cooperation with International famous brands Siemens Schneider Flender Omron ABB WEG Falk Fuji etc. Our company continuously imports over 1000 international first-class high precision processing equipment such as multistage machining centers, CNC lathes and CNC milling machines from Korea, Japan etc. All our processes strictly adhere to CE certification, IS09001 and 2008 quality management system. And we have 12 months quality warranty time. We testing the machine performances before each delivery. Jwell service engineers will always be here for anything you needed.

Usually it takes about 1 – 4 months depends on different machinery upon receipt of order advance payment.

Once clear your requirements and determined extrusion line is ideal for you. We will send technical solutions and Proforma Invoice to you. You can pay via TT bank transfer, LC as you like.

One. We provide both customized extrusion lines and technical solutions. Welcome contact with us for technical innovation or improvements for your future purchasing plan.

We produce more than 2000 advanced extrusion lines every year world wide.

We can send the small spare parts by air express for urgent matter. And the complete production line by sea to save the cost. You can either use your own assigned shipping agent or our cooperative forwarder. The nearest port is China Shanghai, Ningbo port, which is convenient for maritime transportation..

Yes, we support our business partners by pre-after sale service. Jwell has more than 300 technical testing engineers traveling world wide. Any cases would be responded with prompt solutions. We provide training, testing, operation and maintenance service for a life time.

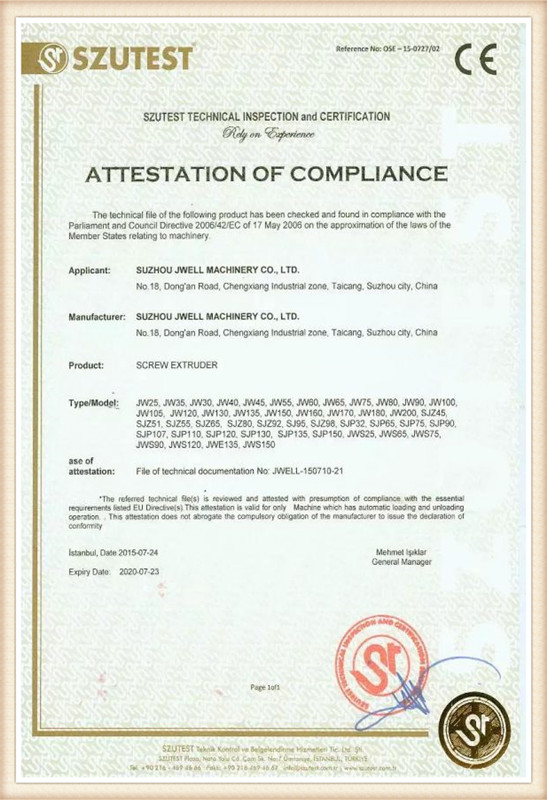

Certificates

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: Other

Design, Development, Manufacture And Sales Of Intellectual Property Rights Management For Plastic Machine

2016-06-14 ~ 2019-06-13

Certified By: Other

Design, Development, Manufacture And Sales Of Plastic Pipe And Sheet Extrusion Production Line

2018-11-20 ~ 2021-11-19

Certified By: Quality Austria Training, Certification and Evaluation Ltd.

Plastic Extrusion Line

2010-01-29 ~